With the first hull nearly ready to be turned over, the rudder must be fitted.

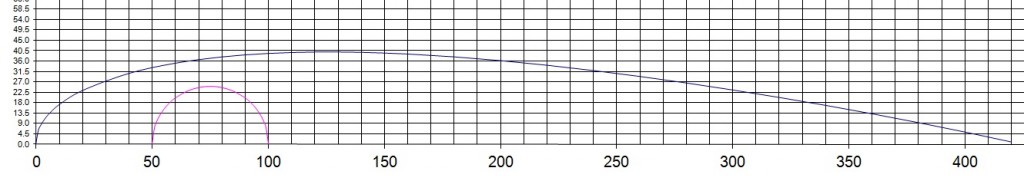

The design specifies the rudder post to be made using 48mm 316SS pipe, which is embedded into laminated plywood. I again used the NACA foil profile as was used on the keel. As for the keel, I implemented the formula in a spreadsheet, and used that the create a number of points in the cross section. This table of offsets was then used to create a chart of the rudder cross section, showing the size of each piece in the lamination, and was exported into the software that drives the CNC to create a foot in hardwood.

This is the scaled chart of the rudder cross section:

… and this table is the list of numbers that came out of the formula.

| Half Thickness of Rudder | Distance from leading Edge |

| 0.00 | 0 |

| 5.67 | 1 |

| 7.95 | 2 |

| 11.10 | 4 |

| 13.45 | 6 |

| 17.05 | 10 |

| 23.21 | 20 |

| 30.67 | 40 |

| 35.13 | 60 |

| 37.86 | 80 |

| 39.38 | 100 |

| 39.98 | 120 |

| 39.85 | 140 |

| 39.12 | 160 |

| 37.90 | 180 |

| 36.25 | 200 |

| 34.25 | 220 |

| 31.94 | 240 |

| 29.36 | 260 |

| 26.54 | 280 |

| 23.49 | 300 |

| 20.24 | 320 |

| 16.78 | 340 |

| 13.12 | 360 |

| 9.26 | 380 |

| 5.17 | 400 |